Válvula de bola flotante CLASE 150 ~ 600

Clase 150 ~ 600

Diseño y fabricación: API 6D, API 608 o BS5351

Dimensiones de las superficies: ANSI B16.10

Fin de bridas ANSI B16.5 Dimensiones:

Prueba: API 6D o API 598

Tipo de conexión:

Brida RF y RTJ termina con la norma ANSI B16.5.

Brida BW termina con la norma ANSI B16.25.

Tipo de Operación

palanca

Dimensiones de conexión del actuador del engranaje de gusano, actuador eléctrico, actuador neumático con la norma ISO 5211.

Construcciones electricidad antiestática "AS" y construcciones de fuego seguro "FD"

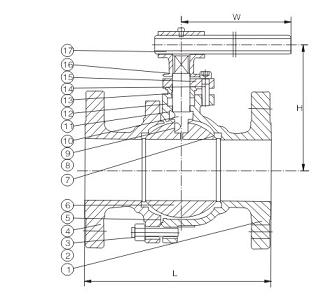

Standard Material Specifications

|

NO. |

Part Name |

Carbon Steel to ASTM |

Stainless Steel to ASTM |

||||

|

WCB |

LCB |

CF8 |

CF8M |

CF3 |

CF3M |

||

|

1 |

Body |

A216 WCB |

A352 LCB |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

|

2 |

Bonnet Nut |

A194 2H |

A194 4 |

A194 8 |

|||

|

3 |

Bonnet Bolt |

A193 B7 |

A320 L7 |

A193 B8 |

|||

|

4 |

Cap |

A216 WCB |

A352 LCB |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

|

5 |

Gasket |

SS Spiral Wound/Graphite or SS Spiral Wound/PTFE |

|||||

|

6 |

Ball |

A105/Ep.Cr or F6 |

A182 F6 |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

|

7 |

Seat Ring |

RPTFE or POM |

|||||

|

8 |

Small Spring |

Stainless Steel |

|||||

|

9 |

Small Ball |

A182 F304, A182 F316L |

|||||

|

10 |

Stem |

A182 F6 |

A182 F6 |

A182 F304 |

A182 F316 |

A182 F304L |

A182 F316L |

|

11 |

Stem Seat |

PTFE |

|||||

|

12 |

Stem Packing |

Graphite or PTFE |

|||||

|

13 |

Gland |

A182 F6 |

A182 F304 |

A182 F316 |

A182 F304L |

A182 F316L |

|

|

14 |

Gland Bolt |

A193 B7 |

A193 B8 |

||||

|

15 |

Gland Flange |

A216 WCB |

A351 CF8 |

||||

|

16 |

Positionling Plate |

Steel |

|||||

|

17 |

Wrench |

A216 WCB |

|||||

This material is according to ASTM standard.

Dimensions (mm) And Weights (kg)

|

Class |

DN |

mm |

15 |

20 |

25 |

40 |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

|

NPS |

in |

1/2 |

3/4 |

1 |

1-1/2 |

2 |

2-1/2 |

3 |

4 |

6 |

8 |

10 |

|

|

150 |

L(RF) |

mm |

108 |

117 |

127 |

165 |

178 |

191 |

203 |

229 |

394 |

457 |

533 |

|

in |

4.25 |

4.6 |

5 |

6.5 |

7 |

7.5 |

8 |

9 |

15.5 |

18 |

21 |

||

|

L1(BW) |

mm |

140 |

152 |

165 |

190 |

216 |

241 |

283 |

305 |

457 |

521 |

559 |

|

|

in |

5.5 |

6 |

6.5 |

7.48 |

8.5 |

9.5 |

11.13 |

12 |

18 |

20.5 |

22 |

||

|

L2(RTJ) |

mm |

119 |

129.7 |

139.7 |

178 |

191 |

203 |

216 |

241 |

406 |

470 |

546 |

|

|

in |

4.69 |

5.11 |

5.5 |

6.9 |

7.5 |

8 |

8.5 |

9.5 |

16 |

18.5 |

21.5 |

||

|

H |

mm |

59 |

63 |

75 |

95 |

153 |

165 |

195 |

213 |

272 |

342 |

495 |

|

|

in |

2.3 |

2.5 |

2.95 |

3.74 |

6.02 |

6.5 |

7.68 |

8.39 |

10.7 |

13.5 |

19.5 |

||

|

Do(W) |

mm |

130 |

130 |

160 |

230 |

400 |

400 |

600 |

850 |

1100 |

1500 |

350* |

|

|

in |

5.1 |

5.1 |

6.3 |

9 |

15.74 |

15.74 |

23.62 |

33.46 |

43.3 |

59 |

13.8 |

||

|

WT(Kg) |

RF |

2.3 |

3 |

4.5 |

7 |

15 |

20 |

25 |

40 |

97 |

160 |

240 |

|

|

BW |

2.0 |

2.5 |

3.8 |

5.8 |

12 |

17 |

21 |

36 |

92.8 |

154 |

227 |

|

Class |

DN |

mm |

15 |

20 |

25 |

40 |

50 |

65 |

80 |

100 |

150 |

200 |

|

NPS |

in |

1/2 |

3/4 |

1 |

1-1/2 |

2 |

2-1/2 |

3 |

4 |

6 |

8 |

|

|

300 |

L(RF) |

mm |

140 |

152 |

165 |

190 |

216 |

241 |

283 |

305 |

403 |

502 |

|

in |

5.5 |

5.98 |

6.5 |

7.48 |

8.5 |

9.5 |

11.13 |

12 |

15.88 |

19.75 |

||

|

L1(BW) |

mm |

140 |

152 |

165 |

190 |

216 |

241 |

283 |

305 |

457 |

521 |

|

|

in |

5.5 |

5.98 |

6.5 |

7.48 |

8.5 |

9.5 |

11.13 |

12 |

18 |

20.5 |

||

|

L2(RTJ) |

mm |

151 |

164.7 |

177.7 |

202.7 |

232 |

257 |

298 |

321 |

419 |

518 |

|

|

in |

5.95 |

6.48 |

7 |

8 |

9.13 |

10.13 |

11.75 |

12.63 |

16.5 |

20.38 |

||

|

H |

mm |

59 |

63 |

75 |

107 |

153 |

165 |

195 |

213 |

272 |

342 |

|

|

in |

2.3 |

2.5 |

2.95 |

4.2 |

6.02 |

6.5 |

7.68 |

8.39 |

10.7 |

13.5 |

||

|

Do(W) |

mm |

130 |

130 |

160 |

230 |

400 |

400 |

600 |

850 |

1100 |

1500 |

|

|

in |

5.1 |

5.1 |

6.3 |

9 |

15.74 |

15.74 |

23.62 |

33.46 |

43.3 |

59 |

||

|

WT(Kg) |

RF |

2.5 |

3.5 |

5.5 |

10.5 |

20 |

25 |

31 |

52 |

118 |

200 |

|

|

BW |

2.1 |

3 |

4.8 |

8.7 |

17 |

22 |

28 |

48 |

105 |

185 |

|

Class |

DN |

mm |

15 |

20 |

25 |

40 |

50 |

65 |

80 |

|

NPS |

in |

1/2 |

3/4 |

1 |

1-1/2 |

2 |

2-1/2 |

3 |

|

|

600 |

L(RF) |

mm |

165 |

190 |

216 |

241 |

292 |

330 |

356 |

|

in |

6.5 |

7.48 |

8.5 |

9.5 |

11.5 |

13 |

14 |

||

|

L1(BW) |

mm |

165 |

190 |

216 |

241 |

292 |

330 |

356 |

|

|

in |

6.5 |

7.48 |

8.5 |

9.5 |

11.5 |

13 |

14 |

||

|

L2(RTJ) |

mm |

163.4 |

190 |

216 |

241 |

295 |

333 |

359 |

|

|

in |

6.43 |

7.48 |

8.5 |

9.5 |

11.63 |

13.13 |

14.13 |

||

|

H |

mm |

59 |

63 |

75 |

107 |

153 |

165 |

195 |

|

|

in |

2.3 |

2.5 |

2.95 |

4.2 |

6.02 |

6.5 |

7.68 |

||

|

Do(W) |

mm |

130 |

160 |

160 |

230 |

600 |

850 |

1250 |

|

|

in |

5.1 |

6.3 |

6.3 |

9 |

23.62 |

33.46 |

49.25 |

||

|

WT(Kg) |

RF |

7.5 |

10.5 |

14.5 |

18.5 |

38 |

56 |

66 |

|

|

BW |

6 |

8.7 |

11 |

14.7 |

31 |

49 |

58 |

* Gear desgastados o actuador eléctrico operado.